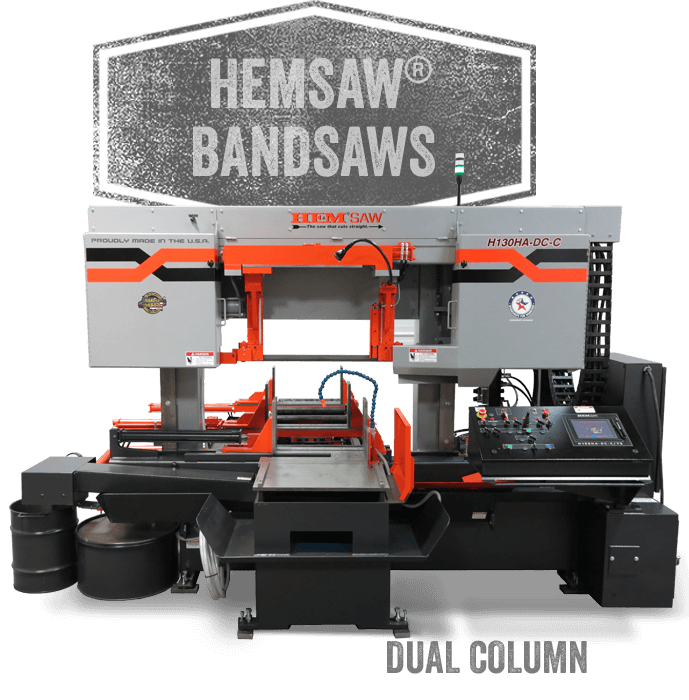

G & M Bandsaw

Manual Band Saws Attend

While it might not appear like much, the band saw is actually one of most crucial tools that every woodworker should own in his workshop.

Bandsaws also allow you to adjust your speed and can make mitered, angled, or even circular cuts, depending on what the table surface is.

G & M Bandsaw